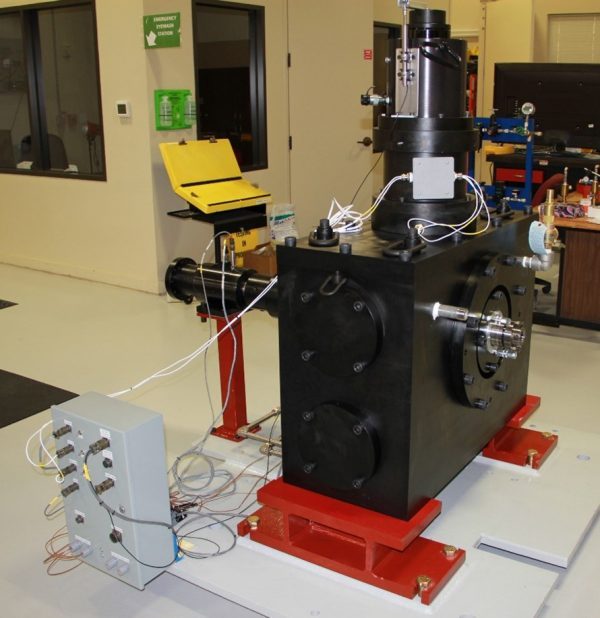

Journal Bearing Friction and Wear Test Fixture

Kalsi Engineering, Inc. (KEI) designed and assembled a journal bearing test fixture that is capable of measuring bearing torque, bearing force, and bearing wear. The bearing torque and bearing load are essential parameters for calculating bearing coefficient of friction (COF). The bearing material coefficient of friction and wear rate are important tribological characteristics and affect the performance and life of bearings used in downhole mud lubricated applications. The ability to validate bearing performance prior to use in downhole applications provided invaluable information used to improve equipment reliability. KEI was selected to design the test fixture based on our design team’s expertise in design, structural strength, fatigue, high pressure/high temperature sealing technology, and tribology.

Bearing coefficient of friction is calculated using the measured bearing torque (Tb) at the test specimen bearing location and the transverse shaft load (or bearing load (Fbearing)) acting between the bearing and shaft and the bearing radius (Rb) . The equation for bearing COF is given as

COF = Tb / (Rb * Fb)

Accurately measuring the bearing torque at the test specimen location is complicated by the fact that developing a transverse load (bearing load) at the test specimen requires the shaft to be supported at two additional locations. The two additional bearing locations are referred to as the support-bearing locations. The reaction forces at the bearing-support locations act in the opposite direction as the bearing load on the specimen. Because of the importance in obtaining accurate bearing torque at the test bearing location, a successful fixture design required minimizing frictional torque at the support-bearing locations.

Bearing lubricity is a key parameter that affects coefficient of friction and wear. The fixture was designed to supply cooling water at the shaft-to-bearing interface at pressure and temperature conditions similar to those in downhole applications. The mass flow rate of the cooling water was maintained at the same levels as experienced in downhole applications.

The bearing test fixture was capable of generating a controlled bearing load (transverse load) between 1,000 lbf to 75,000 lbf on a journal bearing while rotating at speeds up to 400 RPM. The fixture included a two-stage cooling system to remove the heat generated at the bearing surface.

The test fixture is capable of measuring the following parameters:

- Bearing friction torque

- Bearing wear rate

- Bearing temperature

Click here to contact KEI and learn more of what our design team can do for you!