Flow Testing and CFD to Determine Disc Shape Effects

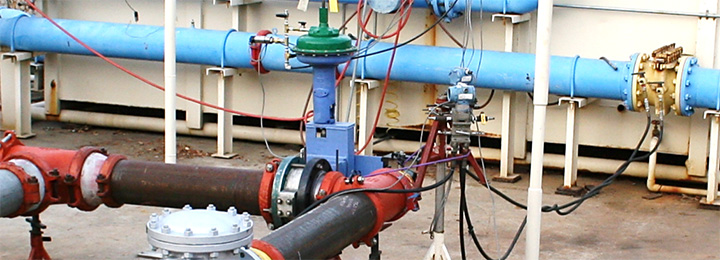

Kalsi Engineering Inc. (KEI)™ has been actively involved in developing improved semi-empirical analytical models for predicting hydrodynamic torque. There are many factors that influence hydrodynamic and aerodynamic torque on a butterfly valve disc. Factors include disc geometry and position, pipe orientation (i.e., presences of flow disturbances, and fluid media). KEI completed an extensive matrix of Computational Fluid Dynamics (CFD) analyses to develop valuable insights into different flow phenomena and their effects on hydrodynamic and aerodynamic torque. The CFD matrix included discs and operating conditions what had been evaluated by KEI through flow loop testing. These CFD results and flow loop test data provide invaluable insights and coefficients that are used to develop the methodology in the Kalsi Valve and Actuator program KVAP®.

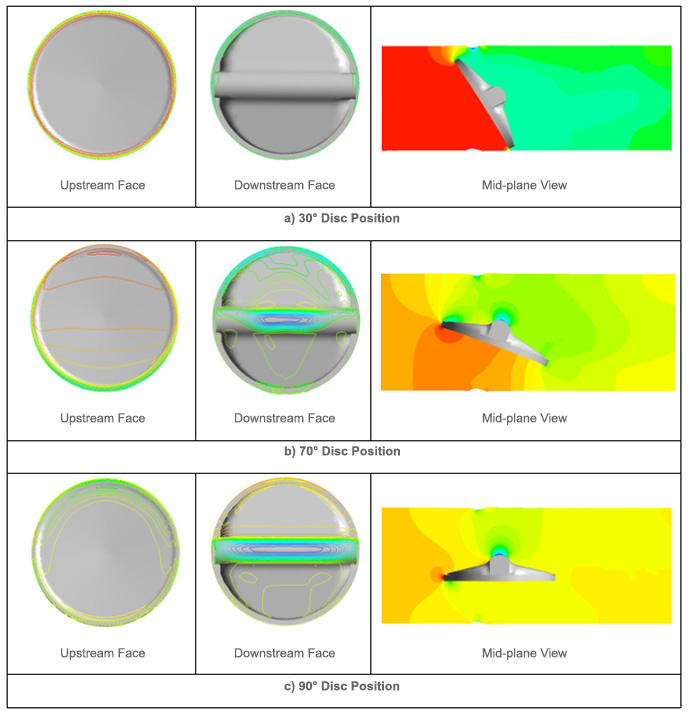

The CFD matrix included multiple disc designs. CFD analyses were performed on these discs design installed in the shaft upstream and downstream configuration and for both compressible and incompressible flow. Pressure coefficient contours/profiles from for the shaft downstream orientation are provided as Figure 1.

The CFD results provided insight into what factors dominate hydrodynamic and aerodynamic torque. The results from this study provide the means to develop more accurate relationships between key disc geometry and hydrodynamic torque coefficients. More accurate coefficients and predictions can then be used to reclaim operating margin.