Flow-Generated Sound Measurements and Pipe Vibration using the KEI Flow Loop and Anechoic Chamber

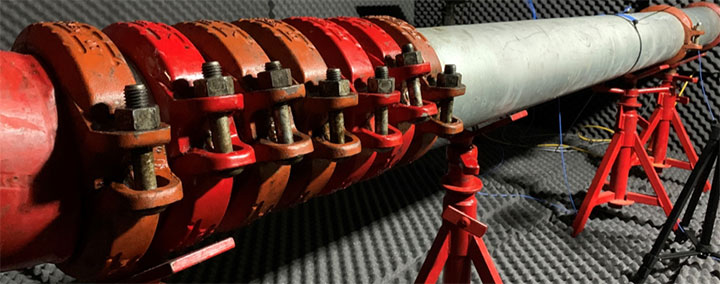

KEI™ flow loop facility is located in Sugar Land, TX. The main test section consists of a rapidly reconfigurable test section piping, a 7,500-gallon reservoir, a 180 HP diesel engine-driven variable speed centrifugal pump, and all associated piping for the actual test sections. The flow loop can deliver 2,700 gpm and pressures up to 270 psig. This flow rate corresponds to a flow velocity of 30 feet per second in a 6-inch pipe. Additional pump equipment can be connected to the system to achieve higher flow rates.

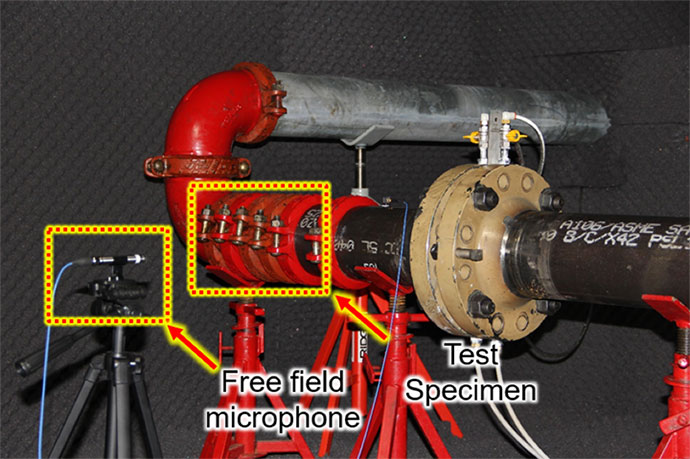

The anechoic chamber (see Figure 1) has a footprint of 12’ x 12’ and is 8’ tall. The walls, floor, and ceiling are constructed to both reduce sound transmission through the chamber wall and to absorb sound generated inside the chamber. The sound blocking insulation inside the wall is rated with a Sound Transmission Coefficient (STC) of 51! This combined with the inner and outer walls help ensure that no external sounds will affect our testing. The walls, floor, and ceiling inside the chamber are paneled with acoustic foam and foam board to reduce echoing and reverberation. The acoustic foam has an excellent Noise Reduction Coefficient (NRC) which ensures sound generated inside the chamber will be absorbed. The chamber has two windows to allow penetration of the flow loop piping and the chamber itself has ample room to easily perform testing activities (see Figure 2). The flow loop and anechoic chamber can be used to perform testing according to IEC 60534-8-2.

In house sound and vibration measurement equipment includes:

- A free-field microphone that has a frequency range of 3.15Hz to 20 kHz and has a sensitivity of 50mV/Pa.

- A triaxial accelerometer with frequency ranges of 0.5 Hz to 3kHz with a maximum vibration range of 5g,

- A triaxial accelerometer with frequency ranges of 0.5 Hz to 3kHz with a maximum vibration range of 10g.

Determining the sound and vibration associated with your test specimen will be no problem with KEI’s flow loop and anechoic chamber. Get in touch today to see how our solutions can serve you.