Elastomer FEA

Kalsi Engineering, Inc. has been actively involved in developing the elastomeric products using finite element analysis (FEA). FEA of elastomers is significantly challenging and requires an insight into the material deformation from the mechanics point of view. Hyperelastic material models are used for the FEA of the elastomeric products. The analyst may choose from a variety of hyperelastic material models. Answers to the following questions should be sought by the analyst before performing hyperelastic FEA:

- Which hyperelastic material model should be used?

- How to obtain the constants necessary to develop the material model?

- Is it necessary to obtain elastomer stress-strain data even to perform preliminary elastomer FEA?

- What kinds of tests need to be performed to obtain the stress-strain data to devise the hyperelastic material model?

- What if the developed material model is unstable? Can the instability be eliminated?

- What if the expected maximum strain in the elastomeric component is beyond the range of the test stress-strain data from which the material model is developed? Or in short, how to utilize the limited test data?

- What are the limitations of the hyperelastic material models?

Our years of experience and strong knowledge base enable us to provide a comprehensive consulting service in the area of elastomer FEA.

Analysis Examples

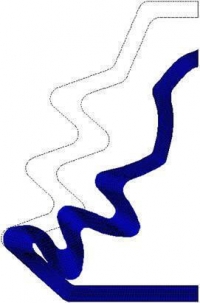

- Simulation of the deformation behavior of a rubber boot under external fluid pressure

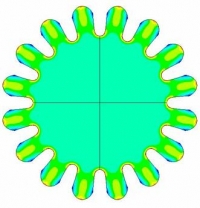

- Elastomer o-ring simulation under fluid pressure to understand o-ring sealing capability