Using Extra Wide Kalsi Seals as RCD Seals

We often recommend 655-Series Extra Wide Kalsi Seals for use in lubricant overpressure-type rotating control devices (RCDs) because of their overall robustness, and relatively low cost. We can design them to replace existing RCD seals, or can assist you in implementing them into entirely new hardware designs.

How Kalsi Seals are used in RCDs

In a typical lubricant overpressure-type RCD, the bearing lubricant is maintained at a pressure that is greater than the pressure of the drilling fluid that is being retained. The lower rotary seal partitions the drilling fluid from the bearing lubricant, and the upper rotary seal retains the pressure of the bearing lubricant, and prevents its loss to the environment. (We offer KLS® and BDRP Seals™ for lubricant underpressure systems.)

Why extra wide seals are preferred as RCD seals

RCD seals face difficult challenges, including relatively high surface speeds, high differential pressure, and significant mandrel runout and deflection. Unless the RCD incorporates a floating seal housing or a floating backup ring, the extrusion gap must be large enough to accommodate the lateral motion of the mandrel. A small extrusion gap can result in metal-to-metal contact that damages the seal, the mandrel, and the seal housing. Conversely, the large extrusion gap clearance that is needed to accommodate mandrel runout and deflection leads to seal damage at higher operating pressures.

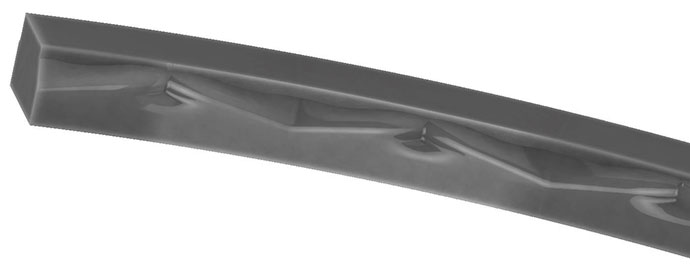

When used as RCD seals, the extra dynamic lip width of the 655-Series seals provides robustness, helping the seals bridge large extrusion gaps, and providing extra sacrificial material to accommodate high pressure extrusion damage. At the same time, the Enhanced Lubrication™ waves of the 655-series RCD seals provide lubrication to the dynamic sealing interface, allowing relatively cool seal operation — although circulation may still be required for cooling at higher speeds. By keeping the seal cooler, the temperature-related modulus loss at the extrusion gap is significantly less, compared to non-hydrodynamic seals.

Why Dual Durometer Seals™ are recommended for pressure retention in RCDs

Because of the high pressures that RCD seals are exposed to, and because breakout torque is often a concern, we recommend that the pressure retaining seal have Dual Durometer™ construction. With such seals, a higher modulus, more extrusion resistant inner layer of elastomer is loaded against the mandrel by a lower modulus outer layer. This reduces interfacial contact pressure and breakout torque in low differential pressure operation, so there is less risk that the drill string will rotate within the stripper element of the RCD. This also places the more extrusion resistant layer of the RCD seal against the extrusion gap.

How to purchase Extra Wide Kalsi Seals™

For available sizes of 655-Series RCD seals, click here. Additional sizes can be manufactured, if desired. Seal purchase orders and requests for RCD seal quotes should be sent to the attention of Seal Sales via e-mail, or by fax at 281-240-0255. For assistance with seal-related RCD engineering questions, click here.