Dealing with Mandrel Misalignment in Rotating Control Devices

The mandrel of a rotary control device (RCD) can experience significant lateral misalignment relative to the seal housings. Because the components of an RCD are large, the manufacturing tolerances and component mounting clearances tend to be relatively large. The bearing internal running clearance may also be relatively large.

In a lubricant overpressure type of RCD, the bearing lubricant is typically pressurized to a value that exceeds the pressure of the drilling fluid. This pressure expands the bearing housing, further increasing the bearing mounting clearance.

The accumulation of the various clearances allows significant lateral misalignment between the mandrel and the seal housings. The misalignment problem is exacerbated by heavy side loads caused by imperfect mounting of the RCD.

If the misalignment causes metal-to-metal contact between the mandrel and the seal housing, the RCD seal may be destroyed by three different mechanisms. First, friction can generate enough heat to melt the seal, allowing it to extrude easily. Second, the contact can chunk the carbide running surface of the mandrel, creating roughness that rapidly cuts and abrades the seal. Third, the contact can produce sharp burrs on the seal housing that cut the seal.

This web page describes several ways of dealing with mandrel deflection in lubricant overpressure-type RCDs. In summary, one can either make the extrusion gap bore large enough to accommodate the lateral misalignment of the mandrel, or one can implement hardware that allows a closely fitting extrusion gap bore to align on, and follow the lateral motion of, the mandrel.

Using a Large Extrusion Gap Bore to Avoid Metal-to-Metal Contact

One way to accommodate mandrel misalignment is to make the extrusion gap bore of the seal housing large enough avoid metal-to-metal contact. This produces a large extrusion gap clearance, which is difficult for an RCD seal to successfully bridge in high differential pressure conditions. With a large gap, delicate seals will be consumed rapidly by pressure-induced extrusion damage.

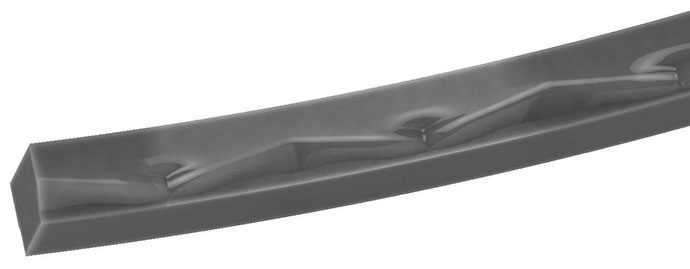

We typically recommend Extra Wide Seals™ or Plastic Lined Seals™ for lubricant overpressure type RCDs with large extrusion gaps. Contact us for selection assistance, or to request a quote for theses unique high pressure seals. The exceptionally wide dynamic lip of these seals helps to bridge relatively large extrusion gaps. The innovative hydrodynamic waves provide interfacial lubrication that reduces seal-generated heat. This reduces temperature-related modulus loss, which helps to maintain extrusion resistance. For best results in higher speed operation, RCD seals should be cooled via circulation. In order to use Extra Wide or Plastic Lined Kalsi Seals™, the lubricant overpressure system must be able to accommodate the hydrodynamic pumping related leakage of the rotary seals.

The lubricant pressure-induced expansion of the bearing housing can be minimized by placing the pressure-retaining RCD seal below the bearings, so that the pressure of the bearing lubricant can be maintained at atmospheric pressure. This configuration helps to maintain better radial guidance of the mandrel, but brings the pressure-retaining seal near the mud-to-lubricant partitioning seal. This brings the heat fields of the seals closer, which can have negative effects on the seals unless circulating cooling is provided. Submit a contact form for more information. For off-the-shelf sizes of RCD seals, see our shaft seal catalog.

Using a Laterally Floating Backup Ring to Accommodate Mandrel Misalignment

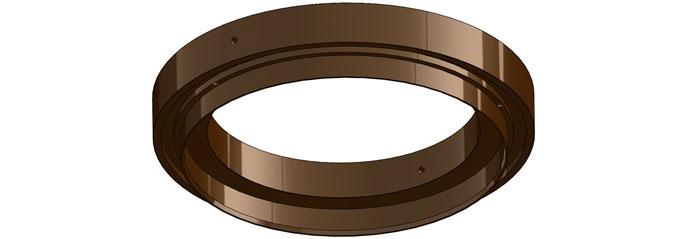

The optimum way to accommodate mandrel misalignment is to use our patented floating metal backup ring, which follows lateral motion in the same manner as a floating seal housing. One advantage the metal backup ring provides is the ability to tune out nearly all pressure-related distortion. This advantage becomes increasingly important when sealing large diameter mandrels, because it permits the use of smaller extrusion gap clearance. Another advantage is the axial compactness. Contact our engineering staff to discuss licensing, and to learn the key steps of engineering a floating metal backup ring.

Using a Laterally Floating Seal Housing to Accommodate Mandrel Misalignment

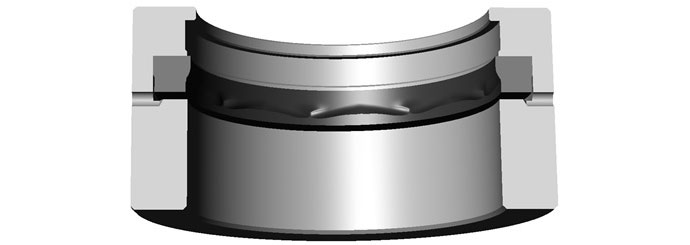

Another way to accommodate mandrel misalignment is to use a floating seal housing that is positioned laterally by the mandrel, and follows lateral motion. Such seal housings are hydraulically force balanced in the axial direction, to ensure freedom of lateral motion. The ability to move laterally allows a relatively small extrusion gap clearance to be used, without the risk of heavily loaded metal-to-metal contact. Unlike the floating metal backup ring described above, the floating seal housing requires the use of a stepped shaft.

The extrusion gap of a floating seal housing tends to close slightly as pressure is applied, due to the presence of a slight radial pressure imbalance. This pressure-related deformation must be considered when designing the seal housing. Contact us to discuss the fine points of engineering a floating seal housing for use with our high-performance RCD seals.