Using Kalsi Seals in high pressure swivels

What is a Swivel?

Swivel definition — A swivel is a mechanism that conducts a fluid between or around relatively rotatable components.

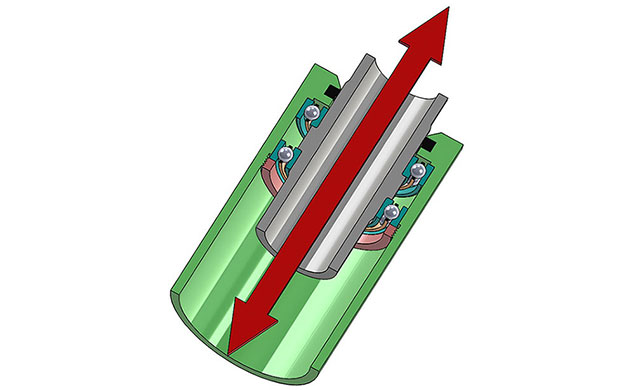

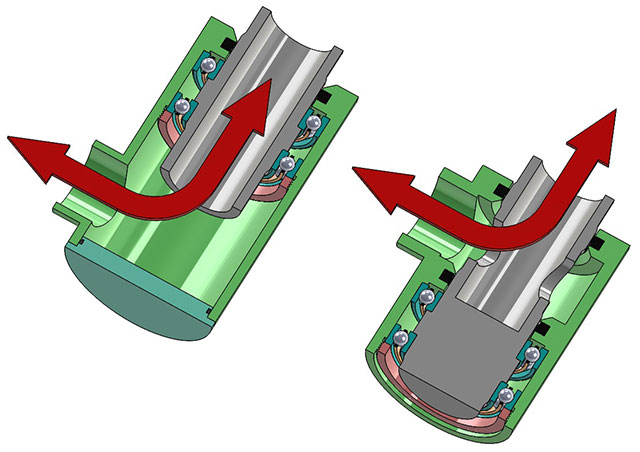

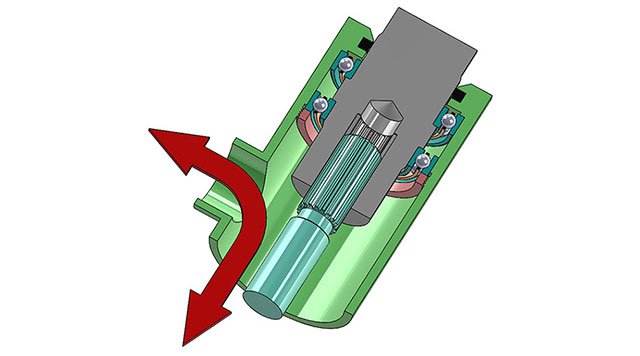

Types of swivels — There are three basic types of swivels: coaxial, side port, and diverter. The key features that define these three types of swivels are illustrated below. Each type can be configured for conducting a lubricant (such as hydraulic fluid) or for conducting a non-lubricating process fluid.

Seals are critical components — Swivel seals are an essential part of any swivel design, because they establish sealing between the relatively rotatable components, direct the flow, and retain the pressure of the fluid. Sealing challenges increase with pressure and speed, and many seals that are marketed as high pressure swivel seals are simply not up to the job.

At Kalsi Engineering, we offer patented high pressure swivel seals that make the most of our pioneering research in hydrodynamic lubrication. By lubricating the dynamic sealing interface during rotation, our swivel seals have less friction, which means less wear and less loss of material properties due to seal-generated heat. This allows our seals to run at higher pressures and speeds than cap seals and other conventional swivel seals. Learn more about our swivel seal options below.

What Are the Types of Swivels?

Swivels can be divided into three broad categories:

- Coaxial Swivels: A coaxial swivel conducts fluid between axially aligned, relatively rotatable conduits. Typically, one of the conduits is guided for rotation by bearings and the other conduit is stationary. Swivel seals establish sealing between the relatively rotatable conduits, preventing fluid loss, and directing the flow from one conduit to the other.

- Side Port Swivels: Alternatively referred to as side entry swivels, side inlet swivels, and side feed swivels. A bearing guided mandrel rotates inside a housing and fluid is conducted between a radially oriented port in the housing and an axially oriented passage in the mandrel. The swivel seals provide dynamic sealing between the housing and the mandrel, guiding the flow between the housing and mandrel. More than one fluid circuit can be incorporated.

- Diverters: Sometimes classified as swivels or pumps, diverters communicate with the annular region surrounding a rotating shaft.

These three principal types of swivels are illustrated schematically below. For the sake of simplicity, the schematics represent swivels conducting a pressurized lubricating fluid that is suitable for lubricating the seals and bearings. Swivels that conduct a non-lubricating fluid typically require additional seals to partition the non-lubricating fluid from the seal lubricant and may require the pressure of the seal lubricant to be equal to or greater than the pressure of the non-lubricating fluid. Contact Kalsi Engineering for additional information.

From these simple schematics and descriptions, it should be clear that a wide range of rotating machinery is represented by the three principal types of swivels. The suitability of Kalsi-brand seals for any given application is typically determined by factors such as pressure, speed, heat transfer, available space, the ability to incorporate and maintain a lubricant reservoir, etc.

What Are the Key Challenges in High Pressure Swivel Sealing?

The challenges that high pressure swivel seals are exposed to vary depending on whether the conducted fluid has abrasive or lubricating qualities. For example, oilfield washpipe assemblies and cement heads conduct extremely abrasive fluids, while a high-pressure hydraulic swivel, on the other hand, conducts a clean fluid with lubricating qualities.

The rotary seal challenges also vary depending on the speed of rotation. For example, a typical hose swivel occasionally rotates by a few degrees or a few revolutions, while many other types of swivels rotate continuously.

These and other challenges associated with high pressure swivel sealing are explained in more detail below. Seal selection and swivel design are based on the unique challenges of specific applications.

Hardware Pressure Breathing

One problem common to many high pressure swivels is component pressure breathing. Hardware components experience dimensional changes as high internal pressure is applied. As the component dimensions change, the extrusion gap clearance, bearing mounting clearance, and lateral shaft motion increase, reducing the life and pressure capacity of the swivel seals. The problem increases with pressure and component diameter.

Kalsi Engineering provides several complementary solutions for hardware pressure breathing. One solution is seals with higher modulus linings and wider dynamic lips for improved pressure resistance with the larger extrusion gap clearance. Another solution is our patented floating backup ring arrangements. These arrangements make the extrusion gap clearance immune to pressure-induced expansion of the pressure housing and largely isolate the seal from lateral shaft motion. The floating backup rings are adaptable to multi-port hydraulic swivels, side port process fluid swivels, coaxial swivels, and diverter arrangements.

Our rotary seal handbook teaches how to implement floating backup rings using a simple stacked housing arrangement. In side entry hydraulic swivels and side port-type process fluid swivels, this arrangement also isolates the bearings from the effects of pressure breathing.

Seal-Generated Heat

Another challenge for swivel seals is seal-generated heat. As the differential pressure across a swivel seal increases, the interfacial contact pressure between the seal and the mandrel increases. This increases friction and causes increased heat and wear during rotation. These problems are accelerated by higher rotary speeds, further increasing the temperature and rate of wear. The increased temperature reduces the modulus of the seal material, increasing the rate of pressure-related extrusion damage.

Kalsi-brand swivel seals address these challenges by using the rotation of the swivel to hydrodynamically pump a thin film of lubricant into the dynamic sealing interface between the seal and the mandrel. This lubricating film reduces friction between the seal and the mandrel, effectively reducing heat and the rate of wear. The cooler operation increases high-pressure seal performance, while the reduced wear extends the functional lifespan of the seal. In some types of swivels, supplemental cooling can be provided to further cool the seals.

Reversing Differential Pressure

In typical hydraulic swivels that use traditional cap seals, the seals can be exposed to differential pressure acting on either side of the seal. These reversing forces can cause deformation and seal shuttling, which in turn can introduce lubricant between the O-ring and the plastic cap, and between the O-ring and the groove. Often, the result is undesirable slippage of all or part of the cap seal.

This seal slippage due to differential pressure in hydraulic swivels can be avoided by using Plastic Lined Kalsi Seals™ in an arrangement that only puts differential pressure across the seals in a single direction. This eliminates the adverse deformation and seal shuttling associated with reversing pressures. Unlike cap seals, the plastic liner of our highest-pressure capacity seal is bonded to the elastomer so there is no possibility of slippage between the liner and the elastomer. The difference between the breakout friction of the plastic and elastomer portions assures that relative rotation occurs at the seal-to-shaft interface.

For hydraulic swivels with reversing pressures of 1,000 psi or less, consider the BDRP™ swivel seal. This seal also has a bonded plastic liner and is designed for differential pressure acting from either side of the seal.

Third Body Wear

Third body wear of the seal can be a significant issue in swivels that conduct high-pressure abrasive fluids. This is because the differential pressure acting on a swivel seal can drive the abrasives into the dynamic sealing interface. High-pressure packing rings, which are typically used in coaxial washpipe assemblies, are especially susceptible to this third body wear due to the fabric texture of the packing rings, and a lip load that eventually becomes very light in the absence of differential pressure.

The typically recommended practice with Kalsi Seals is to partition the abrasive fluid from the seal lubricant with a seal that is exposed to little or no differential pressure. This requires a lubricant pressure that is equal to or slightly above the pressure of the abrasive fluid being conducted by the swivel. One rotary seal partitions the abrasive fluid from the seal lubricant, and the other retains the lubricant pressure. This division of function between two seals prevents the high pressure from forcing abrasive fluid into the dynamic sealing interface, thereby abating third body wear.

Obvious simplifications are possible when the fluid being conducted can be used as a seal lubricant.

What Is the Recommended Implementation for High-Pressure Hydraulic Swivels?

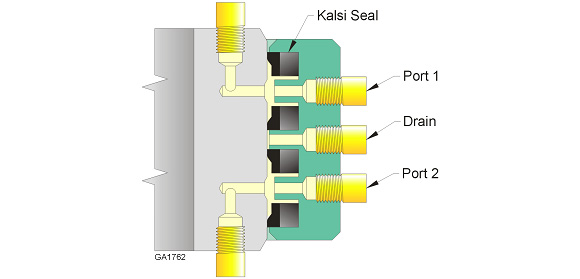

In multi-port hydraulic swivels, a pair of Kalsi Seals is typically used to define each hydraulic circuit. Floating backup rings can be used for extreme pressure applications, in combination with the stacked housing arrangement. Regardless of whether the floating backup rings are used, a bolt-on bearing housing arrangement isolates the bearing housings from pressure breathing and helps to minimize runout of the mandrel.

For hydraulic swivels that have high pressure while rotating, Kalsi Seals with the Enhanced Lubrication™ wave pattern are the preferred choice because of their ability to lubricate with low-viscosity lubricants. For more information on variations of this design, refer to the resources listed below.

Plastic Lined Kalsi Seals have the highest pressure capacity, followed by Dual Durometer Kalsi Seals™. In applications that are sensitive to startup torque, Plastic Lined Seals™ or Dual Durometer Seals™ with a low friction treatment are recommended.

What Are Additional Resources on Swivel Seals?

Kalsi Engineering provides a breadth of resources for appropriate seal implementation so that your design team can overcome the challenges associated with designing high pressure swivels. These include:

Seal Handbook: The Kalsi Seals Handbook™ provides detailed information about designing high pressure swivels. Representing the collective wisdom of Kalsi Engineering senior staff members, the handbook is an invaluable reference manual for individuals interested in using our high pressure swivel seals. For information about specific types of swivels, reference the following chapter links:

- Chapter E2 describes the use of Kalsi seals in multi-port hydraulic swivels. In addition to showing how to use Kalsi-brand swivel seals in conventional hydraulic swivel designs, Chapter E2 also shows how to use floating backup rings in hydraulic swivels using the general stacking housing arrangement that is shown in Chapter D17.

- Chapter E4 and Chapter C15 describe the use of Kalsi Seals in high-pressure washpipe assemblies (coaxial swivels) that conduct abrasive fluid.

- Chapter E5 describes recommended design practices for high-pressure side port swivels that conduct abrasive fluid. This chapter also explains the general stacking housing arrangement, as previously discussed, which isolates the bearing housings from pressure breathing and helps to assure minimal runout of the mandrel.

- Chapter E1, Chapter E6, and Chapter E7 describe the use of Kalsi Seals in diverter-types of swivels.

Hydraulic Swivel Seal Brochure: Our hydraulic swivel brochure shows detailed images and schematics for using Kalsi Seals in side port swivels to define multiple hydraulic circuits.

Contact Kalsi Engineering for More Information

Kalsi Engineering can help your organization find the best solution for your high pressure swivel application. With extensive industry knowledge and experience working with a wide variety of applications, you can trust Kalsi Engineering for high-quality products and advice.

Contact Kalsi Engineering today to learn more about our high pressure swivel seals, and how to implement them.