Introduction to BDRP swivel seals

BDRP seals (Bi-Directional Rotation and Pressure) are patented rotary seals engineered to generate hydrodynamic lubrication with high differential pressure acting from either side and with rotation in either direction. This makes them an excellent seal for high pressure hydraulic swivels.

The key advantage that BDRP seals provide over Cap Seals and Glide Rings, seals commonly used in hydraulic swivels, is much higher pressure and speed capability for longer durations. The increased seal capability leads to longer more reliable equipment operation and is achieved by significantly lowering the seal friction and wear through hydrodynamic lubrication.

We are pleased to announce successful high pressure rotary testing of BDRP seals using a hydraulic oil commonly used in hydraulic swivels. In previous blogs we reported successful high pressure rotary testing of BDRP seals using higher viscosity grade (VG) oils.

Hydraulic swivel seal testing

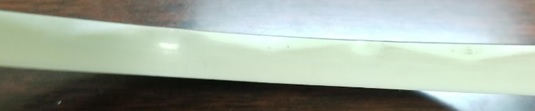

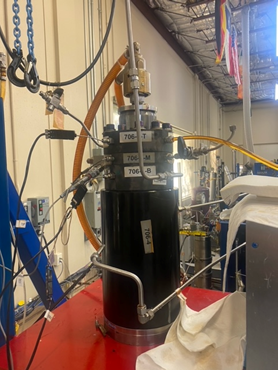

Two tests of 4.5” (114.3mm) diameter BDRP seals (PN 717-2-318) were run on a shaft rotating at 220 RPM (259 sfpm or 1.32 m/s) with an ISO 68 VG oil pressurized to 1,000 psi (6.89 MPa) on one side of the BDRP seal and the oil vented to atmosphere on the other side. The tests were run for 216 hours and 210 hours. The used test seals are in excellent condition. One of the test seals is shown in Figure 1. The test fixture is shown in Figure 2.

Additional hydraulic swivel seal testing

We also completed a 10.49” diameter BDRP seal (PN 717-11-318) test on a shaft rotating at 120 RPM (329 sfpm or 1.67 m/s) with a 68 VG oil pressurized to 1,000 psi (6.89 MPa) on one side of the BDRP seal and 5 psi on the other side. The test ran for 115 hours and the used seal is in excellent condition. A repeat test, scheduled to run for 200 hours, will be started soon.

Using BDRP Seals in your hydraulic swivel

Kalsi Engineering has decades of experience with hydraulic swivels. Contact our helpful engineering staff to discuss implementing BDRP seals in existing or new high pressure hydraulic swivels. We also offer implementation guidance in our seal handbook. We look forward to helping you meet your high-pressure hydraulic swivel needs.