Kalsi Engineering has been conducting 10,000 psi tests directed at increasing the pressure capacity of hydraulic swivels, washpipe assemblies, and similar applications. Our previously reported 320-hour and 368 hour tests of 4.500″ rotary shaft seals at 10,000 psi were conducted with an ISO 68 viscosity grade seal lubricant. We have now completed an intentionally shorter duration 10,000 psi test with an ISO 46 viscosity grade (VG) lubricant. This test was conducted to explore the viability of using a lower viscosity seal lubricant at such extreme pressure.

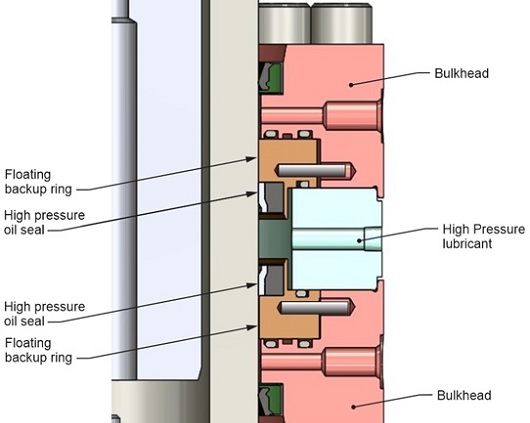

The test setup is shown in Figure 1. The 10,000 psi ISO 46 VG lubricant was retained by a pair of PN 750-1-318 “Super Wide” Plastic Lined Seals™ mounted in our patented floating metal backup rings. The PN 750-1-318 seals incorporate hydrodynamic waves that pump a thin film of lubricant between the shaft and the sealing lip during rotation to minimize friction, heat, and wear. The metal backup rings are designed to follow shaft runout. This feature allows the clearance bridged by the rotary shaft seal to be very small, maximizing the pressure capacity of the seal.

The test was rotated for 127.13 hours, and then disassembled for seal inspection because the 90 hour test goal had been exceeded. The test included 108.38 hours at 120 rpm and 18.75 hours at 20 rpm. At 120 rpm the hydrodynamic pumping related leak rate per seal ranged from 9.35 to 15.49 ml/hr. At 20 rpm the leak rate per seal ranged from 1.31 to 2.43 ml/hr.

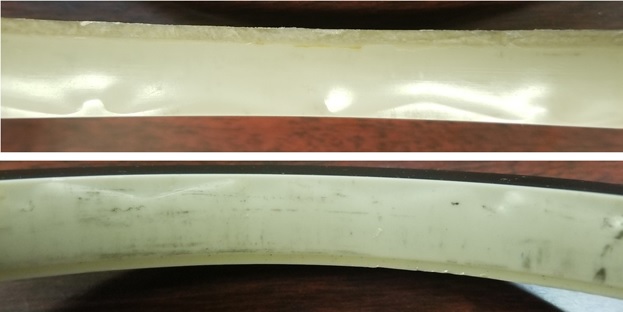

Figure 2 shows the used seals after the test. For reasons unknown, the upper seal normally fares better in this test fixture, and this test was no different. Although both seals have some pressure-related damage along the low pressure edge of the dynamic lip, the damage only extends over a small fraction of the total lip width and both seals could have continued operation.

Contact our staff for assistance with high pressure seal selection and implementation.