In late 2019 we blogged about concentric and eccentric testing of Kalsi-brand rotary seals with dynamic lips that were significantly wider than those of our 507-series Wide Footprint Seals™. The purpose of the significantly wider dynamic lip is to provide better extrusion resistance when used with large mandrel-to-housing extrusion gap clearances. Those seals had the same nominal 0.345” (8.76mm) radial cross-section and 0.036” (0.91mm) radial compression as typical 507-series Wide Footprint Seals.

Oilfield mud motor sealed bearing assemblies are using larger extrusion gap clearances because of increased shaft deflection at the rotary seal. In recognition of the increase in shaft deflection, we manufactured and tested 2.75” (69.85mm) PN 756-3-11 mud motor seals that have a nominal 0.425” (10.80mm) radial cross-section and 0.045” (1.14mm) radial compression. This is 25% more radial dimensional compression than the 0.345” (8.76mm) cross-section seals provide.

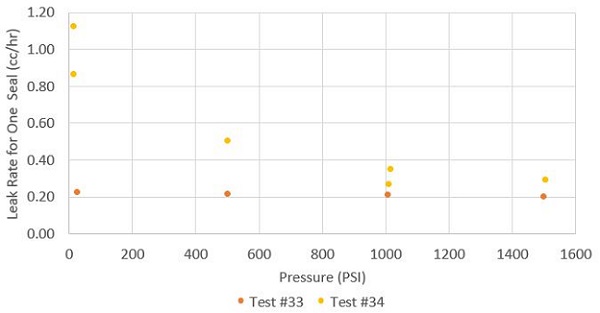

The testing was performed at 480 rpm (345.6 sfpm) in concentric operating conditions. The purpose of the testing was to evaluate if the hydrodynamic pumping rate of the larger cross-section seals was in a useful range for typical sealed bearing mud motor reservoir sizes. Since hydrodynamic pumping related leakage increases with lower temperatures and higher viscosity lubricants, an ISO 460 viscosity grade lubricant was used, and the bulk lubricant temperature was maintained at 162°F (72.22°C). Two tests were conducted at 15, 500, 1,000, and 1,500 psi (1.03, 34.47, 68.95, and 103.42 bar). Since the purpose of the tests was to collect leak rate data, the test durations were relatively short, at 78.52 and 116.73 hours, and an air environment was used. The leak rate of the PN 756-3-11 seals (Figure 1) is in a range that is practical for use in sealed bearing mud motors. The used condition of one of the test seals is shown in Figure 2. Additional testing will be performed to evaluate performance of these larger cross-section seals with 0.010” intentional shaft runout.

These larger cross-section mud motor seals can be made for any mandrel diameter. Tooling for the 0.425” (10.80mm) cross-section seals can also be adapted to manufacture 0.345” (8.76mm) cross-section seals. For additional information contact our engineering staff.