Cement Pump Seal Testing

The K-Cartridge™ cement pump seal cartridge replaces the stuffing box of the mixing and charging pumps that are used on of oilfield well-cementing trucks. The K-Cartridge was developed through intensive testing on a centrifugal pump in our Sugar Land, Texas laboratory. The pump used a reduced size impeller to circulate a cement-analog sand slurry through a small test loop (Figure 1). Testing was performed with 2.000” diameter cement pump seals, a rotary speed of 2,400 rpm, and a lubricant supply pressure of 60 psi.

More than 50 separate tests were performed. By testing in the laboratory, we were able to carefully monitor performance of an evolutionary series of prototype cement pump seal assemblies and make essential design improvements before going to the field. These design improvements were directed at reducing seal-generated heat, improving heat transfer of the assembly, improving the energizer retention of the lip seals, and adjusting the rotation driven flow that flushes and lubricates the lip seals.

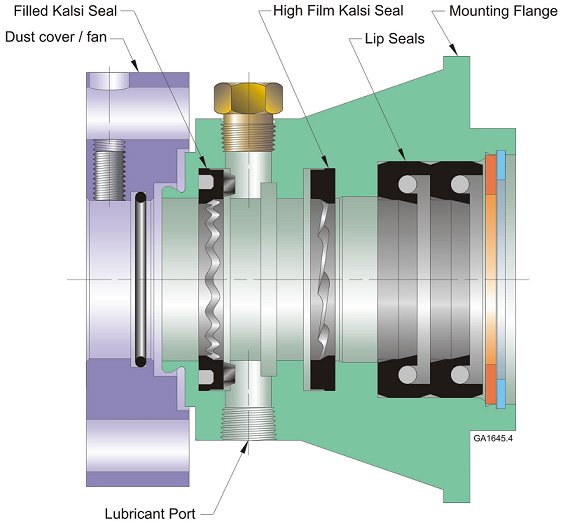

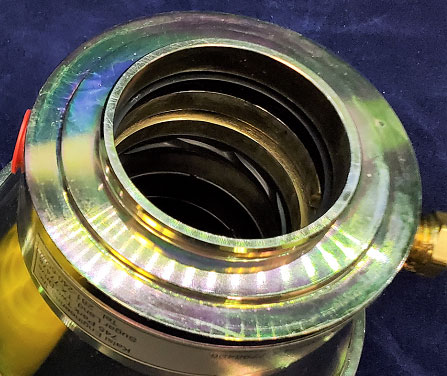

The final version of the K-Cartridge cement pump seal assembly is shown in Figures 2 to 4. A Filled Kalsi Seal prevents loss of the seal lubricant to the atmosphere. A High Film Kalsi Seal serves as a miniature rotationally driven pump that provides a controlled flow of lubricant to flush and lubricate the pair of lip seals that face the volute of the pump and contain the cement. The shaft-driven fan provides forced air cooling to the seal housing, which helps to dissipate seal-generated heat.

Availability and ordering

K-Cartridges are available for 4 x 5 and 5 x 6 Twentieth Century and Gardner-Denver brand centrifugal pumps. Contact Kalsi Engineering for additional information.