Kalsi Engineering, Inc. (KEI), under contract from the Electric Power Research Institute, has developed a new validated methodology for predicting the flow-induced forces in balanced globe valves used in commercial nuclear power plants. These valves are used in critical-to-safety applications. Previous methodologies used by the industry were limited in application or were too conservative to provide reasonable predictions.

The methodology developed by KEI™ is the result of validated computational fluid dynamic (CFD) modeling techniques based on KEI experience and new flow testing commissioned for this project. Figure 1 shows one such test in the KEI test lab. Multiple specimens were tested with differing pipe configurations, system conditions, and valve orientations to produce a test matrix of nearly 500 tests that were evaluated for fluid-induced forces.

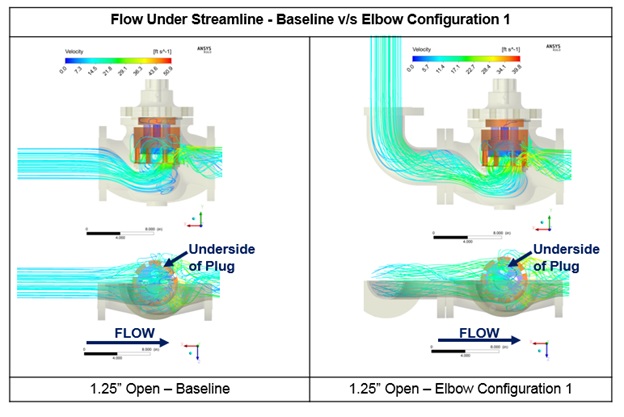

The test data were used to validate a CFD model that allowed parametric study of the key contributors to the flow-induced forces. Over 150 CFD analyses were performed as part of this parametric study. The validation process for the CFD met the rigorous requirements of the Electric Power Research Institute’s quality assurance program and commercial grade dedication processes. Figure 2 shows a comparison of CFD results with a straight run of pipe upstream of the valve versus an elbow installed just upstream of the valve.

With insights from the CFD model, a methodology was developed that met the following project goals.

1. Straightforward approach that can be implemented by power plant engineers

2. Applicable to majority of nuclear power plant applications

3. Bounding predictions that will not overly penalize actuator capability margin

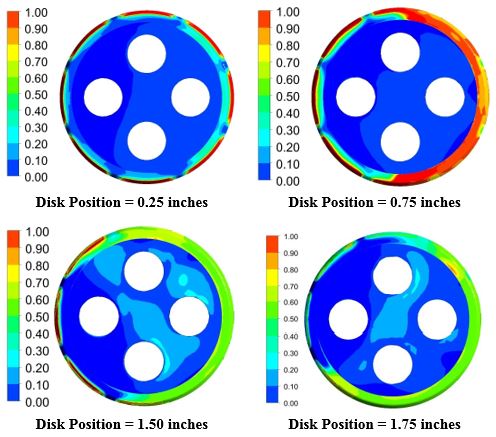

To satisfy this third criterion, the methodology combines the effect of flow-induced forces that act perpendicular to the valve stem axis (side load force) and act in the direction of the valve stem axis (disk differential pressure force). This approach provides a more reasonable prediction than mere summation of these forces. Also, KEI’s research on the disk differential pressure force provided insights related to cavitation and force direction that provide new information to the industry. Figure 3 shows a view of the bottom of the valve disk and how the differential pressure between the top and bottom of the disk varies with stroke position.

KEI considers this new methodology an important tool for the safe operation of nuclear power plants. The development of this methodology with validated CFD modeling and flow loop testing continues KEI’s role in supporting the nuclear industry with innovative products and solutions. To learn more about this methodology and its impact on plant operations, contact our highly experienced Consulting engineering staff.