Circumferential slippage of a seal relative to a housing can produce undesirable effects, such as increased seal and housing temperature and seal and housing wear. Kalsi Seals incorporating anti-rotation tangs (U.S. Patent 8,505,924) haven’t been widely adopted due to the expense of machining matching pockets in the lubricant side groove wall of the seal housing. Because of this, Kalsi Engineering has been evaluating a more economical way to implement Kalsi-brand rotary seals with anti-rotation tangs.

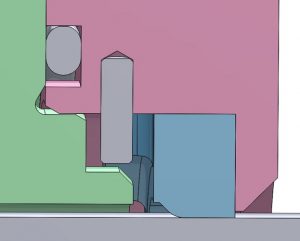

Our evaluation used the test configuration shown in Figure 1. The groove bore of the seal housing was finished smooth, without grit blasting, to encourage seal slippage. The 2.75” rotary seal has molded axially projecting tangs that engage inexpensive radially oriented Type 2A grooved pins. The half-length longitudinal grooves on the commercially available grooved pins create displaced metal that produces mechanical interference when driven into a drilled hole. This interference retains the pins in place. An axial projection from the lubricant-side groove wall prevents loss of the pins if they work loose (patent pending). This axial projection also helps to locate the rotary seal axially — particularly during installation onto the shaft.

Three 480 rpm tests were performed using an ISO 320 viscosity grade lubricant at 15 psi. During rotation, the bulk temperature of the lubricant was controlled to about 200°F. In all of the tests, the static lip and lubricant end of the seal were lubricated with Valvoline W615 multi-purpose grease to encourage slippage. The tangs successfully prevented gross circumferential slippage in all three tests. In the third test, the tangs were initially positioned away from the pins, and during the test enough seal slippage occurred to bring the tangs into contact with the pins. This confirms that the greased seal would have experienced circumferential slippage if not for the tang and pin arrangement. The tangs and pins were intact and undamaged at the conclusion of each test, the rotary seals were in excellent condition.

For additional information on this new seal design, contact our staff.