We are pleased to announce a successful 200-hour-plus test of a 10.49-inch (266.45mm) BDRP Seal™ at 100 rpm and 1,500 psi differential pressure. The used test seal is still in excellent condition and functional at the conclusion of the test (Figure 1). In addition to this test, 10.49” BDRP Seals™ have been tested with 1,000 psi at 170 rpm and with 1,500 psi at 75 rpm.

We believe this extensive testing demonstrates that the BDRP Seal is the most capable rotary seal in existence for use in RCDs that do not have a seal lubricant pressurization system.

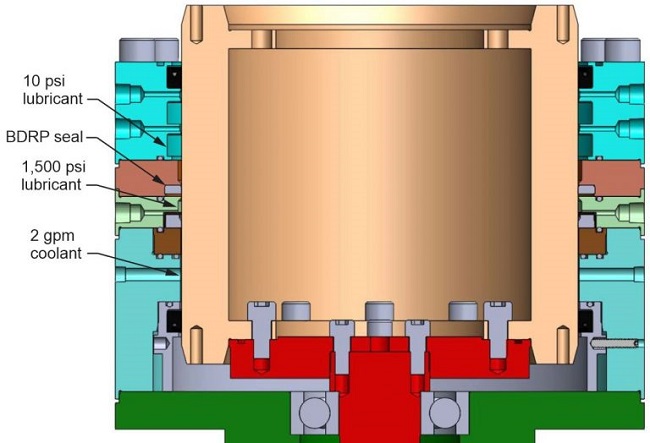

As with the previously reported tests, the 100-rpm test seal was oriented as it would be in an oilfield RCD that does not have a lubricant pressurization system. The hydrodynamic waves of the seal faced upward toward the IS0 320 viscosity grade seal lubricant, and the 1,500-psi test pressure was applied to the underside of the seal. The seal lubricant above the test seal was maintained at a pressure of about 10 psi to assure flow through the restricted lubricant supply tubing of the test fixture. A cross-section of the test setup is shown in Figure 2.

During the 100-rpm test, the hydrodynamic waves pumped a film of lubricant from the low-pressure lubricant chamber, through the dynamic interface, and into the 1,500-psi test fluid at a rate of about 18 ml/hr. In an RCD, this leakage could be returned to the bearing chamber with our patented lubricant return valve (U.S. Patent 10,435,981). Alternately, if the low-pressure bearing lubricant is being circulated through an external lubricant reservoir for cooling purposes, the generous pumping action of the BDRP Seal can be used to lubricate and flush an outboard lip-type barrier seal. Contact our engineering staff to discuss how to implement this exciting new rotary seal in your RCD product line.