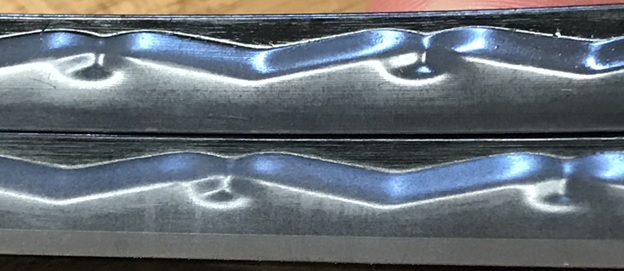

A pair of 10.49” PN 682-21-303 extra wide type A Plastic Lined Seals™ was tested for 100 rotating hours at 2,300 psi (15.85 MPa) and 45 rpm (123.6 sfpm) using an ISO 68 viscosity grade lubricant and a nominal radial extrusion gap clearance of 0.015”. The test included 353 rotational start/stop cycles under full pressure. The seals were in excellent condition at the conclusion of testing, despite operating with such a large extrusion gap clearance. The combined hydrodynamic pumping related leak rate for the pair of seals was 0.42 ml/hour.

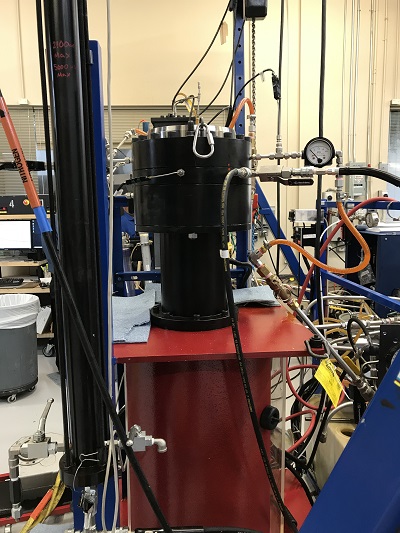

Antifreeze was circulated through a cooling circuit above the pair of seals and through a small heat exchanger at about 0.9 gpm. The coolant entering the test fixture was about 76°F and the coolant exiting the test fixture was about 82 to 85°F. As a result of this modest amount of circulation, the bulk lubricant temperature between the seals ranged from 100 to 120°F. The region below the rotary seals contained stagnant (i.e. non-circulating) oil.

Contact us to learn more about the capabilities of the Plastic Lined Kalsi Seal™.