Kalsi Engineering is pleased to announce a new benchmark in high pressure rotary seal performance. A pair of PN 655-4-114 Extra Wide Enhanced Lubrication Seals™ have been tested at 5,000 psi for 40 days against a 2.75” (69.85mm) shaft rotating at 252 ft/minute (1.28 m/s) with 0.010” (0.25mm) dynamic runout. This is the most severe test of an all-elastomer rotary seal that we have ever conducted. The rotary seals were in good condition at the conclusion of the test, and could have continued to function for a much longer period of time.

The test was designed to replicate the surface speed of a 4.875” (123.83mm) OD washpipe rotating at 200 rpm. This required 350 rpm with the 2.75” test shaft, which subjected the seals to 75% more runout cycles than a 4.875” washpipe operating at 200 rpm. The temperature of the ISO 320 viscosity grade lubricant was maintained at 120 to 130°F (48.9 to 54.4°C) to simulate the anticipated temperature of an oilfield drilling swivel washpipe assembly.

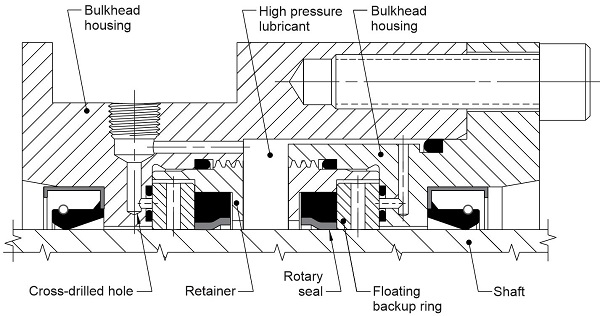

The key to this remarkable high pressure sealing performance was the Dual Durometer™ construction of the rotary seals, and the use of our patented floating backup ring hardware arrangement. The test was terminated due to a leaking O-ring at a static radial sealing location. Based on this result, we have redesigned the floating backup ring assembly to eliminate all radial sealing locations, as featured in Chapter E5 of our seal handbook. The new hardware arrangement uses face seals at all static sealing locations, and is significantly easier to machine and assemble, compared to past designs. The hardware arrangement is compatible with various types of high pressure rotary seal applications, such as drilling swivel washpipe assemblies, rotating control devices (RCDs), hydraulic swivels, side feed cement swivels, and other process fluid swivels with radially oriented inlet ports. Contact us for additional information, or to request a high pressure rotary seal quote. See our shaft seal catalog for available sizes of high pressure seals.