Using Kalsi Seals in RCDs with Lubricant Overpressure

A rotating control device (RCD) reduces formation damage in oilwell drilling (compared to overbalanced drilling) by maintaining the pressure of the annular fluid column of drilling mud at a pressure below, or comparable to, that of the reservoir. The reduction in formation damage helps to optimize the production potential of the well.

Early versions of Kalsi-brand rotary seals began to be used in RCDs in 1991. Since then, several advances in technology enable our seals to operate in more adverse RCD sealing conditions, including higher pressure, higher speed, less cooling, lower viscosity lubricants, and less complicated lubricant supplies.

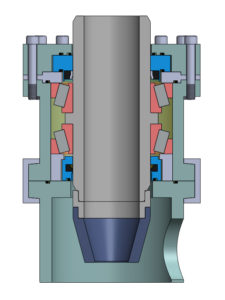

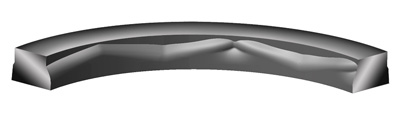

Chapter E01, Using Kalsi Seals in RCDs with lubricant overpressure, provides guidance for implementing Kalsi Seals into the type of RCDs that maintains the seal lubricant at a pressure that is slightly greater than the wellbore pressure. The information in this chapter is also relevant to the design of other types of high-pressure rotating equipment, such as water drilling heads, and includes information on the optional use of floating backup rings.

Seals that are compatible with RCDs that use a non-pressurized seal lubricant system are described in Chapters C17, KLS® high pressure lip seals, and C19, BDRP™ rotary shaft seals, of the Kalsi Seal Handbook™. These chapters provide seal descriptions, performance characteristics, and implementation recommendations for these types of Kalsi-brand rotary shaft seals.

Additional information can be provided by contacting our helpful Kalsi Seals engineering team.