Design

Mechanical Design

Kalsi Engineering has a proven track record in developing new designs and products from concept to full production. Our mechanical design team is supported by our comprehensive analysis and testing capabilities. Our engineers and designers have extensive experience in machining, welding, tooling, and other manufacturing processes used in the fabrication of a broad range of mechanical and structural equipment. We utilize state-of-the-art, computer-aided design software tools to support our design and development activities.

Our accomplishments are reflected by numerous improvements and patents related to valves, static and dynamic seals for demanding applications, downhole drilling tools, bearings, measurement-while-drilling equipment components, wellhead equipment, and unique thread geometries. We have formed world-class alliances to market our technology, and several of our patented products are licensed to multi-national companies for manufacturing and worldwide marketing.

Design & Product Development Capabilities

- Conceptual and detail design of mechanical/structural equipment

- Detailed manufacturing drawings

- Prototype design and fabrication

- Product testing and evaluation

- Development of proprietary/patentable products

- Design of specialized test fixtures

Design Examples

- Custom designed test fixtures

- Custom designed actuator test stands

- Journal bearing friction and wear test fixture

- High pressure, high speed washpipe assembly design for drilling and coring swivels

- Design and development of a new generation of automated welding machines for hard surface overlays on large surfaces

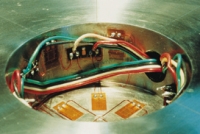

- Design of space station mock-up hardware used for astronaut training in NASA’s Neutral Buoyancy Laboratory

- Sealed bearing assemblies for downhole drilling motors and rotary steerable tools

- An improved wedge gate valve design for critical nuclear power plant applications

- A nonlocking lubricated tapered plug valve design suitable for operation under sharp hydraulic transients

- Design of turbine impellers for downhole power generators to provide the desired speed, torque, and erosion life characteristics

- Design of unique elastomeric thrust bearings to carry high thrust loads in an abrasive environment

- Development of a high-accuracy test stand for qualifying electric motor-powered gear actuators for valves