Much of our rotary seal testing is performed on our battery of standardized 2.75” horizontal test fixtures. While the 2.75” fixtures are excellent for comparing the performance of one seal design to another under identical test conditions, they aren’t always the perfect answer to every conceivable test condition. For example, they aren’t easily adapted to tests using washpipes; they have known limitations when testing larger diameter rotary seals; and they have thermal characteristics that differ from certain real-world rotary sealing applications.

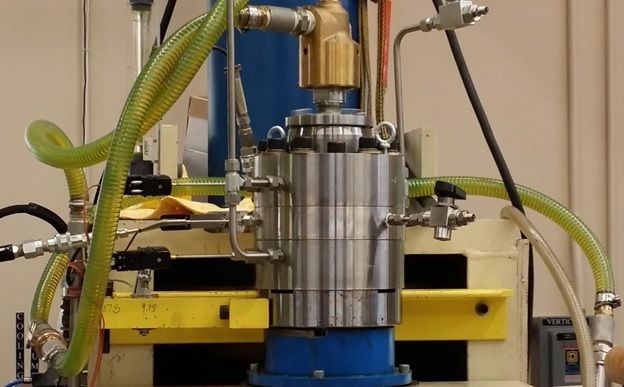

In addition to the horizontal test fixtures, we have a high pressure test fixture with the drive shaft oriented vertically. With this fixture, we have performed dozens of high pressure tests on 2.75” ID Plastic Lined Seals™, including a 1,000 hour continuous rotation test at 7,500 psi across the seals. Most of these tests were directed at high pressure washpipe operating conditions. To better serve the high pressure swivel market, we have adapted our vertical test fixture to test the 4.5” seals used in a 3” bore, 10,000 psi capable washpipe assembly. The objective of the fixture is to better simulate the high pressure sealing location in coaxial and side entry swivels.

The 4.5” fixture components are based on our stacked housing swivel arrangement, and incorporate our patented floating backup rings. When desired, coolant can be circulated through the washpipe for cooling purposes.

The new test setup will allow us to collect leakage data under various temperature, pressure, and speed conditions using seal and backup ring diameters that are appropriate for many high pressure swivel assemblies. The inaugural run of the fixture began in mid-July 2015.

The fixture is driven by a 20-horsepower variable speed motor with a synchronous belt drive. The data acquisition system monitors and records lubricant pressure, rotary speed, running torque, hydrodynamic pumping related leakage, and relevant temperatures, and provides for automatic shutdown if any of the data exceeds predetermined limits.

For high pressure side entry swivel design guidelines, see Handbook Chapter E5 “Using Kalsi Seals in extreme pressure side port swivels” and Handbook Chapter E2 “Using Kalsi Seals in hydraulic swivels”. Contact Kalsi Engineering for sales and technical support.