A new chapter titled “Using Kalsi Seals in side port swivels” has been added in the Application Engineering section of our rotary seal handbook. This new, well-illustrated chapter describes the best practices for designing high pressure side port swivels for use with Kalsi-brand rotary shaft seals.

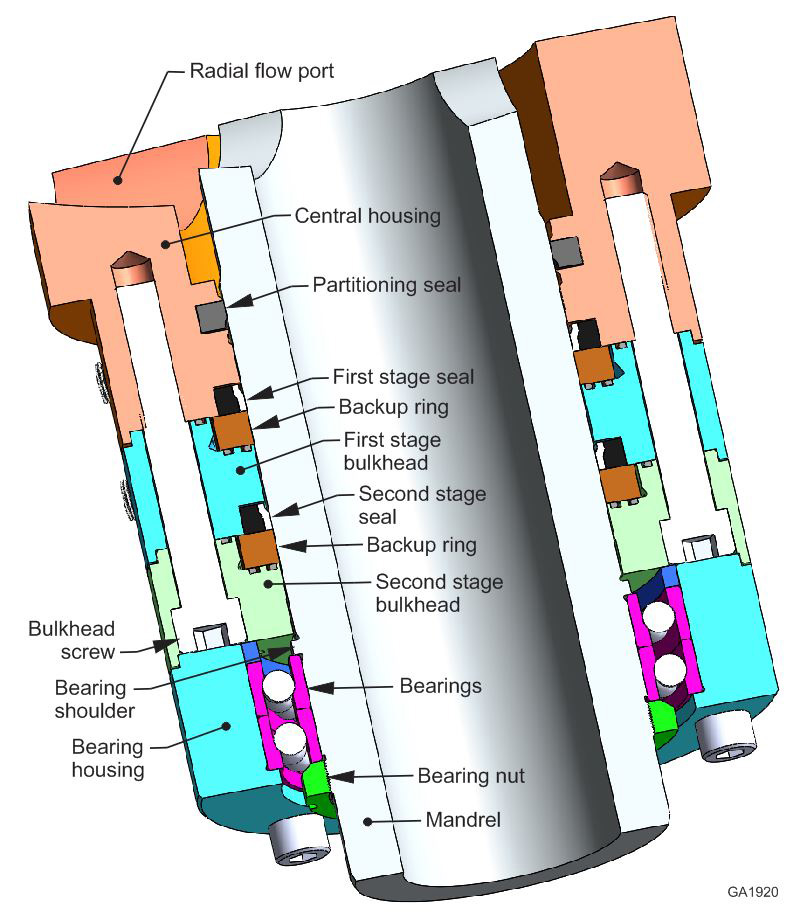

The suggested swivel design incorporates Kalsi Engineering’s patented floating backup rings. These rings provide the smallest practicable extrusion gap for the pressure-retaining seals, which enhances pressure capacity and promotes long sealing life. The design is a modular arrangement that utilizes simple stacked housings to locate the seals, backup rings, and bearings. The housings are bolted to a central housing that incorporates the radially oriented side entry port. This side feed swivel arrangement is robust, economical to manufacture, and simple to assemble and disassemble. It avoids the use of radial O-rings, which are difficult to assemble in large diameters, and can fail in extreme high pressure service. The design minimizes the number of precision machined surfaces, and locates the few that remain in positions that are easily accessible during machining and inspection. It also eliminates the use of custom threads.

Although the new chapter focuses on high pressure side port swivels, the basic stacking housing arrangement is adaptable to other equipment, such as hydraulic swivels, washpipe assemblies, and rotary control devices (RCDs). Contact us for additional information.